In industries such as food, beverages, pharmaceuticals, chemicals, textiles, or hotel laundry, industrial boilers play the role of the “heart” of the energy system. This equipment supplies steam and heat energy for many critical production processes.

However, due to continuous operation under high pressure and temperature, boilers may encounter certain technical issues. If not promptly addressed, these problems can cause production interruptions, increased maintenance costs, and even occupational safety risks.

This article will share 5 common problems in industrial boilers and electric boilers, along with their causes and solutions, helping businesses proactively prevent issues and operate equipment efficiently.

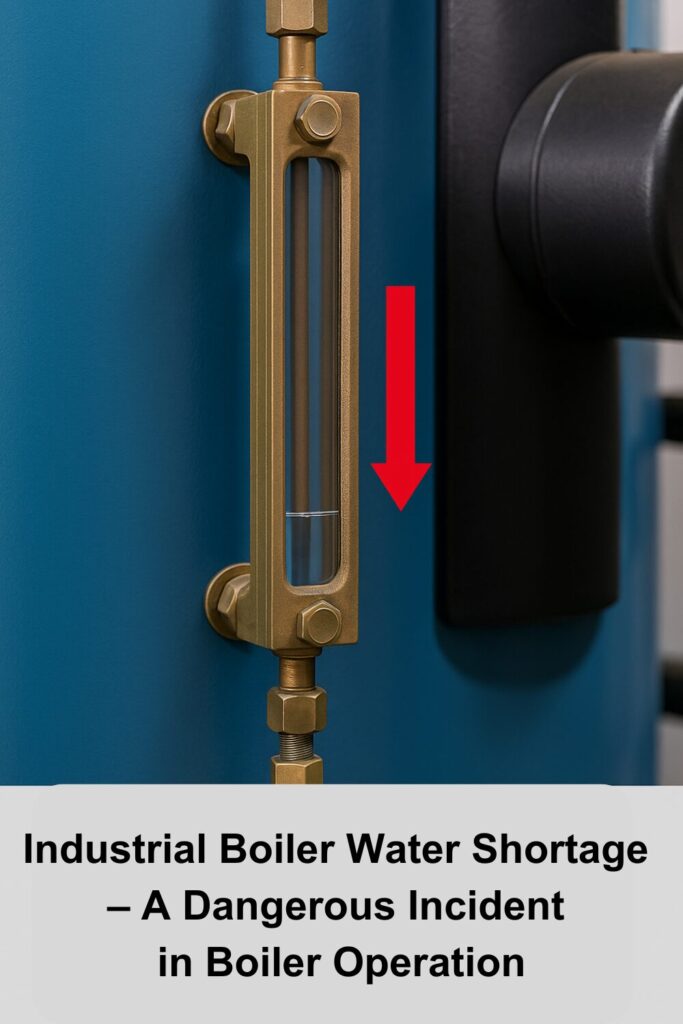

1. Severe boiler water shortage

In operating an industrial boiler, maintaining a stable water level is critical for safe operation. If the water level in the boiler drops too low, the entire steam generation tubes and furnace will be severely affected. This is also one of the most dangerous incidents, as it can lead to explosions, equipment damage, and production line disruptions.

1.1 Symptoms

- Low-water alarm light turns red, alarm siren sounds continuously.

- Steam appears in the sight glass but no water is visible.

- Temperature and pressure in the furnace rise abnormally fast.

- Metal cracking noises may be heard due to excessive thermal expansion.

1.2 Causes

- Operators fail to regularly check the water level.

- Feedwater pump failure, blockage, or power loss.

- Leaking blowdown valve causing continuous water loss.

- Faulty water level sensor or float switch malfunction.

1.3 Solutions

- Immediately shut down the boiler, turn off burners, fans, and feedwater pump.

- Never add water when the boiler is still hot to avoid thermal shock.

- Wait for the boiler to cool down, then inspect steam tubes, sight glass, and feedwater pump.

- Replace faulty sensors, valves, or pumps if necessary.

- Restart the system following proper safety procedures.

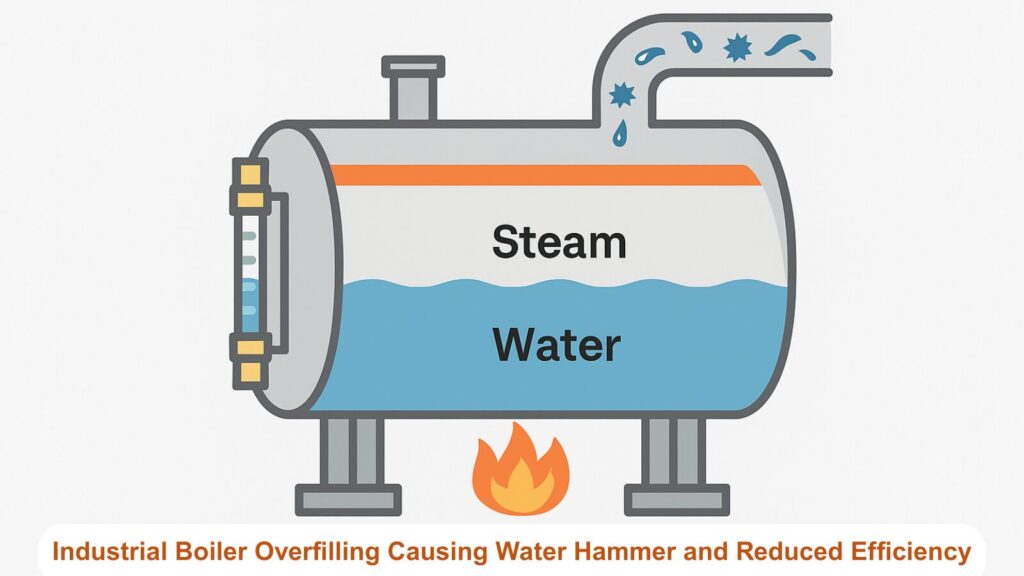

2. Boiler overfilled with water (flooding)

In contrast to water shortage, an industrial boiler being overfilled with water also poses many risks. When water occupies too much space in the steam drum, the amount of steam generated decreases, leading to low efficiency and the potential occurrence of dangerous water hammer in the piping system.

2.1 Symptoms

- Sight glass completely filled with water, no steam visible.

- Steam-consuming equipment operates weakly, with reduced efficiency.

- Loud knocking noises occur in the steam pipeline.

- Pressure reading lower than normal even with high firing rate.

2.2 Causes

- Excessive water supply without monitoring.

- Low steam demand but the feedwater pump keeps running continuously.

- Blowdown valve not functioning or clogged.

- Automatic water level controller malfunction.

2.3 Solutions

- Flush sight glass to accurately check water level.

- Reduce firing rate or adjust flue gas dampers.

- Open blowdown valve to lower water level to permissible limits.

- Inspect and recalibrate the automatic controller.

3. Boiler pressure exceeds safety limit

Industrial boilers operate within a pre-designed pressure range. If exceeded, the safety valve will release steam to protect the system. However, when this issue occurs frequently, it not only compromises safety but also causes energy loss and reduces equipment lifespan.

3.1 Symptoms

- Pressure gauge reading exceeds the safety threshold.

- Safety valve continuously releases steam, emitting a loud hissing sound.

- Pressure gauge base vibrates strongly, with signs of steam leakage.

- In some cases, high temperature is accompanied by system vibration.

3.2 Causes

- Safety valve stuck, not opening or closing correctly.

- Steam generation capacity too high while demand is low.

- Faulty pressure control system.

- Operational error, failure to reduce firing in time.

3.3 Solutions

- Immediately reduce fuel supply and lower firing rate.

- Close dampers to reduce heat input.

- Open vent valves or manually operate the safety valve.

- Perform intermittent blowdown combined with refilling water.

- Send the safety valve for periodic inspection and calibration.

4. Steam tubes rupture, bulge, or burst

In any type of industrial boiler or electric boiler, the steam tube system is subjected to extremely high pressure and temperature. If scaling, corrosion, or overload occurs, the tubes may bulge, rupture, or even explode, posing major risks to operators.

4.1 Symptoms

- Small explosion sounds inside the furnace.

- Strong steam leakage from tube locations.

- Water level in the sight glass drops abnormally fast.

- Sudden pressure drop, system vibration.

-

Industrial boiler steam tube ruptured due to scaling and corrosion

4.2 Causes

- Feedwater untreated, containing excessive minerals and impurities.

- Incorrect boiler operation, sudden load increase.

- Long periods without cleaning, heavy scaling accumulation in tubes.

- Metal corrosion caused by harsh operating environment.

4.3 Solutions

- Immediately stop boiler operation, shut off burners and feedwater pumps.

- After cooling, inspect the entire tube system.

- Replace or weld damaged tubes.

- Establish periodic descaling and cleaning schedule.

- Ensure feedwater quality meets required standards.

5. Steam leakage at pressure parts (valves, flanges, joints)

One common but often underestimated problem is steam leakage at valves, flanges, and joints. Although it may start as a minor leak, if not addressed promptly, it can lead to significant energy loss, higher operating costs, and even safety risks.

5.1 Symptoms

- Hissing sounds and visible steam escaping from joints, valves, and flanges.

- Moisture marks around welds, with steam rising visibly.

- Gradual pressure drop even though the system remains in operation.

5.2 Causes

- Poor-quality welds, substandard installation.

- Corrosion due to untreated feedwater.

- Continuous thermal expansion causing material cracks.

- Equipment aging after long-term operation.

5.3 Solutions

- For minor leaks, monitor and repair during scheduled maintenance.

- For major leaks, shut down the system, reduce pressure to zero, then perform welding or replacement.

- Reinstall pressure-resistant materials that meet standards to ensure long-term safety.

- Perform periodic ultrasonic inspection to detect weak welds early.

These five issues are problems that any business using industrial boilers may encounter. If detected and addressed properly, the equipment will operate safely and stably, contributing to improved production efficiency.

6. Preventive solutions for industrial boiler failures

After reviewing the five common failures, it is clear that most causes come from improper operation, lack of regular maintenance, and poor feedwater quality. Therefore, businesses can minimize risks and maintenance costs by proactively implementing the following preventive measures.

6.1 Regular maintenance and inspection

Industrial boilers are high-pressure equipment, so maintenance cannot be done superficially. Businesses should establish maintenance schedules on a weekly, monthly, and yearly basis, including:

- Daily: check sight glass, pressure gauge, safety valve, and feedwater condition.

- Weekly: perform blowdown to remove sediment, clean water filters.

- Monthly: check valve, flange, and joint tightness; clean furnace chamber.

- Yearly: conduct safety inspection by licensed agencies, ensuring compliance with legal standards for pressure equipment.

Benefits: Helps detect damages early, prevents serious failures, and extends boiler lifespan.

6.2 Use standard-quality feedwater

Feedwater is the “lifeblood” of a boiler. If its quality is poor (high mineral, metal, or impurity content), scaling will accumulate on steam tubes, causing blockage, reduced heat exchange efficiency, and tube bursts.

Solution:

- Install softened water treatment systems or industrial RO systems before feeding water into the boiler.

Regularly check pH, hardness, and impurity levels in water. - Use specialized boiler water treatment chemicals (as recommended by manufacturers).

Example: In food and pharmaceutical industries, using standard-quality water not only protects boilers but also ensures product safety.

6.3 Train professional operators

A common cause of boiler incidents is inexperienced operators. Businesses should invest in training programs covering:

- Basic knowledge: boiler working principles, operational indicators.

- Troubleshooting skills: recognizing abnormal signs and performing emergency actions.

- Occupational safety compliance: fire safety rules, use of protective gear.

Additionally, establish a standard operation manual to ensure all shifts follow consistent procedures.

6.4 Application of automation technology and remote monitoring

Modern electric industrial boilers are often integrated with automatic control systems, enabling real-time monitoring of pressure, temperature, and water levels.

Businesses can upgrade older systems by:

- Installing water level and pressure sensors with display screen alerts.

- Connecting to SCADA software for centralized monitoring from the control room.

- Integrating SMS/email alert systems for incident notifications.

Benefits: Minimizes human error, enhances safety, and reduces staffing needs for on-site monitoring.

6.5 Establishing standard operating procedures (SOP)

A Standard Operating Procedure (SOP) serves as the guideline for all operational tasks. The SOP should include:

- Startup procedure: check valves, water levels, test the safety valve before heating.

- Operating procedure: monitor pressure, temperature, and record operation logs.

- Troubleshooting procedure: outline steps to take in each situation (low water, overfilled water, high pressure, etc.).

- Shutdown procedure: ensure pressure and temperature are safely reduced before stopping.

Practical example: A hotel using boilers for laundry reduced incidents by 40% after implementing a detailed SOP and retraining all staff.

6.6 Selecting electric industrial boiler solutions and integrated industrial heating systems

In addition to operational measures, choosing the right technology is also crucial.

- Electric industrial boilers: safer, no gas emissions, quiet operation, suitable for food and pharmaceutical industries.

- Integrated industrial heating systems: use optimized steam distribution, combine boilers with economizers to reduce fuel consumption.

Value: saves energy costs, extends equipment lifespan, and ensures clean and sustainable production.

Preventing failures in industrial boilers not only protects equipment but is also a key factor in ensuring workplace safety, product quality, and business reputation. By combining regular maintenance, proper feedwater treatment, staff training, technology application, and standard procedures, businesses can operate boilers efficiently while minimizing risks.

7. Conclusion

Safe operation of industrial boilers not only helps businesses maintain continuous production but also reduces repair and maintenance costs. Failures such as water shortage, overfilled water, excessive pressure, tube bursts, or pressure leaks can be fully prevented if properly monitored and handled in time.

If your business is looking for safe, cost-effective, and durable industrial boiler or electric boiler solutions, contact Maruse Engineering today for detailed consultation. We are committed to providing high-quality industrial heating equipment tailored to each production sector.