1. The Role and Main Applications of Boilers in the Food Industry

1.1 What is a boiler? Why is it essential in the food industry?

The concept of “boiler” is very familiar in industrial production. When referring to a industrial boiler, it means a large device used to generate steam or hot vapor at high pressure, supplying heat for multiple production processes. Among them, electric industrial boilers use electricity as the main heat source — ideal for environments that require clean, smoke-free operations. “Industrial furnace” is another common term for boilers, especially for oil, gas, or biomass-fired systems. When mentioning “industrial thermal equipment,” it covers the entire system of steam, heat, heat exchange, and auxiliary units.

In the food industry, using boilers is extremely important because:

- They provide stable steam or heat for cooking, sterilizing, and drying processes.

- They help reduce production time and increase productivity.

- They ensure consistency, product quality, and compliance with hygiene and food safety standards.

1.2 Applications of Steam in Food and Beverage Production Lines

In food processing plants, the steam generated by industrial boilers is widely used for:

- Pasteurization/sterilization (e.g., milk, beverages, canned fish, processed food) to eliminate microorganisms and extend shelf life.

- Cooking or pre-heating (e.g., vegetable and fruit processing, seafood processing, canned food production).

- Drying products (e.g., dried fruits, snacks, food powders) and drying equipment after cleaning.

- Supplying steam for CIP (clean-in-place) systems and automatic cleaning of equipment.

- Providing heat for auxiliary processes such as hot water washing, steaming, and packaging sterilization.

Apart from food and beverages, thermal systems from boilers are also used in other industries such as:

- textiles: supplying steam for dyeing and fabric drying;

- chemicals: heating reactions and vapor processing;

- laundry: steam for ironing and drying;

- hospitality and services: steam for heating and steaming systems.

Therefore, investing in a suitable boiler system not only benefits food factories but also enhances efficiency across multiple industries.

1.3 Real-life Examples in Dairy, Beverage, and Seafood Industries in Vietnam

In Vietnam, many food factories have invested in industrial or electric boilers to meet high production demands.

For instance, seafood processing plants require stable-pressure steam for sterilization, while beverage factories need clean, oil-free steam to avoid affecting flavor. Choosing the right type, capacity, and professional operation improves product quality, reduces energy costs, and ensures food safety compliance.

2. Specific Requirements for Boiler Use in the Food Industry

2.1 Hygiene and Safety Standards for Food Contact

In the food industry, steam from boilers must not only meet pressure and temperature standards but also be “clean steam” — free of oil, smoke, heavy metals, or any impurities that might affect the product. When steam directly contacts food or packaging, these requirements become even stricter. Using an electric industrial boiler can be an excellent choice since it produces no smoke or dust emissions. Additionally, boiler and pipeline materials must comply with food safety standards.

2.2 Compliance with Mandatory Technical Standards: TCVN, QCVN, ISO, ASME

When investing in an “industrial boiler” or “industrial furnace” for a food factory, companies must comply with standards such as: TCVN for boilers, QCVN for emissions, ISO 22000 for food safety, and ASME/EN for pressure vessels. Periodic inspection is crucial to ensure safe operation.

2.3 Ensuring Stability and Continuity in Production Operations

Since food production processes are typically continuous and require stable steam, the boiler system must operate automatically, include regular maintenance, and have backup units to avoid production interruptions. Selecting the right “industrial thermal equipment” helps maintain stability, especially during peak seasons or product changes.

3. Technical and Operational Features of Industrial Boilers for the Food Industry

3.1 Boiler Types Suitable for Different Scales and Product Lines

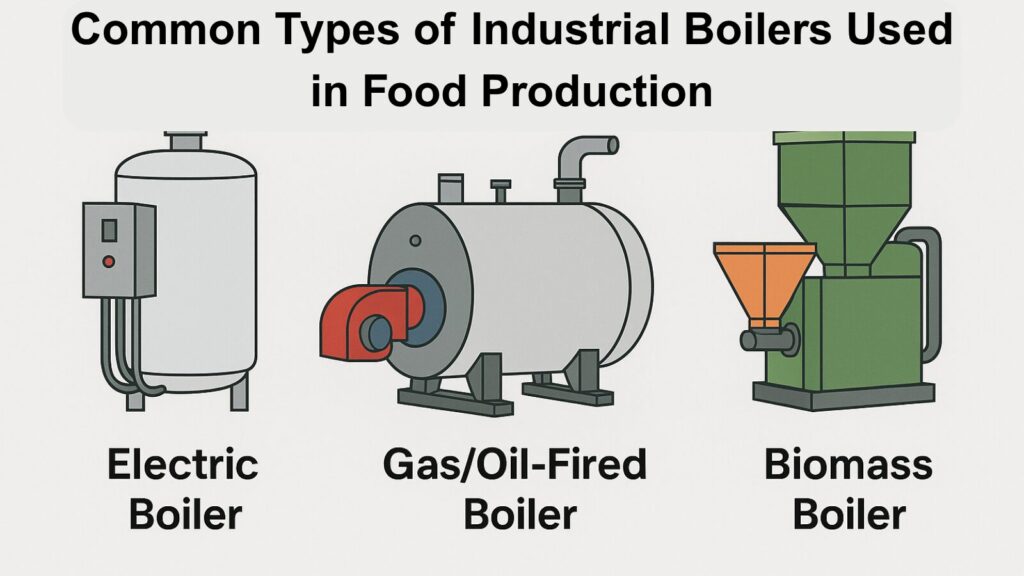

Depending on the production scale and product type, factories can choose from the following:

- Electric industrial boilers: clean, smokeless, easy to control – ideal for high-standard food production.

- Gas/oil/biomass boilers: lower investment cost but require good exhaust treatment systems.

- Fluidized-bed and multi-fuel boilers: flexible operation when fuel sources vary.

Choosing the right type helps optimize operational costs and meet hygiene requirements.

3.2 Key Technical Parameters: Capacity, Pressure, Fuel Type

When designing and selecting boilers, it’s essential to define the required steam capacity, operating pressure, fuel type (electricity, gas, oil, biomass), and future scalability. Choosing an “industrial boiler” with excessive capacity may result in energy waste.

3.3 Solutions for Efficiency and Energy Saving

To operate an “industrial boiler” efficiently, apply solutions such as heat recovery, pipeline insulation, automated control systems, and optimized seasonal operation. Supporting “industrial thermal equipment” can help reduce operational costs and CO₂ emissions.

3.4 Maintenance and Extending Boiler Lifespan in Food Environments

Regular maintenance, safety valve checks, feedwater treatment, and system cleaning are necessary. For food factories, equipment must meet high hygiene standards and operate continuously — proper maintenance extends lifespan and ensures safe operation.

4. Influencing Factors and Challenges in Applying Boilers to the Food Industry

4.1 Steam Quality Directly Affects Product Quality

Steam that fails to meet standards — containing oil, dust, or unstable pressure — can alter product color, flavor, or shelf life. Therefore, proper operation of “industrial boilers” is a key factor.

4.2 Hygiene and Compliance Challenges with International Standards (FDA, USDA)

For export or premium production, when steam directly contacts food (culinary steam), it must meet international standards such as FDA and USDA. This poses major challenges for businesses due to higher requirements for materials, hygiene, and equipment control.

4.3 Emission Treatment and Strict Environmental Regulations

Especially for oil/gas/coal-fired boilers, proper emission treatment according to QCVN and noise reduction are critical. Failure to comply can affect production permits and factory environmental conditions.

4.4 Energy Cost Fluctuations and Fuel Supply

Fuels like gas, oil, and biomass fluctuate in price depending on the market. Thus, designing “industrial furnaces” or multi-fuel systems provides flexibility and better cost control.

4.5 Seasonality and Product Change in Food Production

Agricultural and food industries are highly seasonal, and production changes may alter steam demand. Therefore, steam systems must be flexible, capable of modular or scalable operation.

4.6 Dependence on Technical Skills and Operation Personnel

Given hygiene, reliability, and safety requirements of “industrial thermal equipment,” untrained or inexperienced operators may cause accidents or technical failures that disrupt production and affect products.

5. Conclusion

Investing in a suitable industrial boiler system is a crucial step for food processing enterprises to enhance production efficiency, ensure product quality, and save costs. Attention should be paid to hygiene standards, selecting the right boiler type (including electric boilers for clean and flexible operations), proper operation and maintenance, and meeting the industry’s unique challenges.

If your business is seeking an “industrial furnace” or “industrial thermal system” solution, contact Maruse Engineering for professional consultation and optimal solutions.