Industrial boilers are the heart of many production processes in industries such as food, beverage, chemical, pharmaceutical, textile, laundry, and hospitality. However, the performance of this industrial thermal equipment heavily depends on regular maintenance. In this article, Maruse Engineering provides a detailed guide on proper boiler maintenance steps to help your business operate efficiently and save costs.

In modern production systems, industrial boilers play a central role in providing stable thermal energy for many critical processes. Although they are designed to be durable, over time, these units still require periodic maintenance to ensure safety and operating efficiency. Especially in industries with strict requirements such as food, pharmaceuticals, chemicals, or hospitality, proper maintenance not only reduces the risk of failures but also optimizes operating costs. So how should boiler maintenance be carried out correctly? Is there a specific process for electric industrial boilers?

The article below will provide a comprehensive A–Z guide to maintaining industrial thermal equipment effectively, practically, and easily applicable for businesses.

1. Why is it necessary to maintain industrial boilers?

1.1 Ensuring safety for factories and workers

Boilers operate under high pressure and temperature; if not regularly maintained, they can cause severe incidents that endanger both lives and assets. Maintenance helps detect leaks and damage early, preventing industrial accidents.

1.2 Improving operational efficiency

Scheduled maintenance ensures boilers achieve optimal thermal efficiency, reduce fuel consumption, and prevent unexpected breakdowns. Especially for electric industrial boilers, periodic maintenance ensures stable operation of resistors and control systems, saving energy.

1.3 Extending boiler lifespan

Proper maintenance allows industrial boilers to run reliably, reducing major repairs and saving long-term operating costs. Particularly in systems that operate continuously, such as in food factories or hotels, any operational interruption can cause significant losses.

2. Safety standards in boiler maintenance

For high-pressure and high-temperature equipment like an industrial boiler, maintenance is not simply cleaning or routine inspection. It must strictly comply with safety standards to ensure absolute safety for both the equipment and operators. Below are two critical requirements that any business must clearly understand:

2.1 Compliance with TCVN 12728:2019 and TCVN 8366:2010

TCVN 12728:2019 is the national technical standard regulating the safety inspection of pressure equipment such as boilers. This standard includes initial inspections, periodic inspections, and special inspections (after major repairs or incidents). Businesses must strictly follow the timelines and procedures to obtain operating permits.

TCVN 8366:2010 specifies the design, manufacturing, and testing of pressure vessels. Although boilers are more complex than standard pressure vessels, the requirements in this standard still apply to pressure-bearing parts such as combustion chambers, pipelines, and covers.

For beginners, it can be simply understood that: if a boiler is not inspected or inspected incorrectly, it will not be allowed to operate and poses an extremely high risk of explosion. Regular maintenance in compliance with standards ensures both safety and legality in usage.

2.2 Qualified and trained personnel

Not everyone can carry out boiler maintenance. Personnel assigned to this task must:

- Hold a boiler/steam boiler operation certificate issued by authorities.

- Be properly trained in industrial thermal equipment safety.

- Clearly understand the operating procedures, locations of valves, gauges, controllers, and potential risks.

Improper maintenance, such as draining the boiler while pressure is still high, or opening the inspection hatch when there is still pressure inside, can cause steam explosions, severe burns, or system-wide fire/explosion incidents. Therefore, businesses must pay special attention to selecting highly qualified technical teams or using maintenance services from reputable companies like Maruse to ensure absolute safety.

3. Boiler maintenance cycle procedures

One of the key factors to ensure stable operation of industrial boilers is carrying out maintenance according to a proper cycle. Maintenance should be divided into specific intervals such as daily, weekly, monthly, etc., to ensure no potential risk is overlooked. Below is a standard recommended process that businesses should adopt:

3.1 Daily maintenance

These are basic but essential checks, usually carried out by operating technicians:

- Check operating pressure and temperature: ensure parameters are within the safe design range.

- Short blowdown: remove sediments accumulated at the boiler bottom to prevent scaling and corrosion.

- Check water level and alarm signals: ensure automatic control systems and sensors are functioning accurately.

- Log operational data: monitor abnormal indicators, detect faults early.

Note for beginners: Do not perform blowdown when pressure is high. Only blowdown at the end of a shift, after shutdown, when pressure has dropped to a safe level.

3.2 Weekly maintenance

Every week, a more thorough inspection should be carried out by the maintenance team or technical staff:

- Check safety valves, water pumps, and pressure gauges: ensure measurement devices are accurate.

- Clean burners, combustion chambers, and chimneys: remove soot or ash buildup.

- Test protection systems: overheating relays, low-water sensors, emergency power cut-off systems.

Note: For electric industrial boilers, special attention should be given to checking the control panels and thermal relays.

3.3 Monthly maintenance

This is a semi-detailed inspection, requiring support from engineers or service providers:

- Open boiler shell: check inside for scaling, leaks, or worn parts.

- Measure feed water quality: check hardness, pH, TDS and treat water if standards are exceeded.

- Check insulation and boiler casing: ensure effective insulation and no heat loss.

3.4 Semi-annual and annual maintenance

This is major maintenance (overhaul) to inspect the entire system:

- Clean all fire tubes, chimneys, and steam pipelines.

- Check resistors, insulation, and automatic control systems.

- Replace worn-out parts such as gaskets, seals, sensors, and old valves.

- Conduct technical inspection according to TCVN.

Expert suggestion: Schedule overhauls during production downtime or holidays to avoid affecting factory productivity.

In summary, breaking down and strictly following periodic maintenance schedules not only ensures safety but also helps businesses control costs and minimize unexpected incidents during production.

4. Boiler maintenance during temporary shutdown

In production, there will be times when businesses need to temporarily shut down boilers due to line maintenance, shift adjustments, or long holidays. However, if not handled properly during this period, the equipment may suffer from corrosion, scaling, or severe damage. Below are two common preservation methods during downtime:

4.1 Dry Preservation

This method is applied when boilers are expected to be out of operation for more than 3 months. The goal is to keep the entire interior of the equipment dry to prevent corrosion caused by moisture:

- Step 1: Drain all water from the boiler after shutdown and cooling.

- Step 2: Use dry air or a fan to dry the inside of the boiler shell.

- Step 3: Place desiccants (silica gel, quicklime, etc.) into compartments and the furnace chamber.

- Step 4: Seal all manholes and valves, block chimneys and pipes to prevent moisture ingress.

Note: Periodically check the desiccants and replace if necessary. This is an effective long-term preservation method.

4.2 Wet Preservation

Applied when the downtime is less than 3 months. This method maintains a saturated steam environment inside the boiler to prevent oxygen from contacting the metal:

- Step 1: Clean and fill the boiler with water (preferably treated water to reduce scaling risks).

- Step 2: Heat the boiler gently at around 90–100°C for 30–60 minutes to remove dissolved gases such as oxygen and CO₂.

- Step 3: Seal all valves and outlets to keep the system fully filled under anaerobic conditions.

Note: Do not apply this method if the boiler has leaks or requires major repairs. If not well controlled, the water may become contaminated and cause scaling when restarting the boiler.

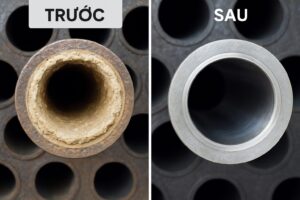

5. Optimizing efficiency and preventing scaling

One of the most common reasons for rapid degradation of industrial boilers is the buildup of scale inside heating tubes, boiler bottoms, and heating elements. Scale reduces heat transfer efficiency, causes localized overheating, and increases fuel consumption. Therefore, businesses should apply the following measures to keep boilers clean and operating at peak efficiency:

Blowdown is a basic but crucial operation to remove insoluble solids in the water:

- Frequency: should be done daily, especially after each operating shift.

- Timing: perform at the end of the shift, after pressure has safely dropped.

- Duration: short, frequent blowdowns are more effective than long ones, helping to avoid excessive heat and water loss.

5.2 Controlling feedwater quality

Feedwater quality directly affects scaling, corrosion, and heat transfer efficiency:

- Use water softening systems: to remove Ca²⁺ and Mg²⁺ ions that cause hardness.

- Regularly measure key indicators: including pH (should be 9–11), alkalinity, conductivity (TDS), hardness.

- Replace water periodically: especially when salt concentration exceeds permissible limits.

5.3 Periodic chemical descaling

For long-term operations, scale can still accumulate even with proper water treatment:

- Descaling chemicals: such as EDTA, phosphate, polymers… can be applied periodically to dissolve light scale.

- Full cleaning: combine chemicals and mechanical cleaning (using soft brushes, low-pressure spray equipment) every 6–12 months.

5.4 Install monitoring and automatic warning devices

To ensure effective control and early warnings:

- Install online TDS sensors: to alert when feedwater conductivity exceeds thresholds.

- Pressure/temperature warning systems: to detect abnormal operating conditions early, reducing scaling risks caused by overheating.

6. Key points in maintaining electric industrial boilers

Electric industrial boilers are increasingly popular thanks to their safety, easy control, and eco-friendliness. However, the electrical system still poses risks if not regularly checked. Below are important points to note during maintenance:

6.1 Inspect the electrical system

- Regularly measure insulation resistance.

- Check relays, thermal relays, and automatic controllers.

6.2 Maintain heating elements

- Clean heating resistors.

- Ensure safety cut-off systems operate reliably.

6.3 Optimize automated operation

- Check PLC control software (if available).

- Ensure automated temperature and pressure adjustments function accurately.

Proper maintenance ensures that electric industrial boilers achieve maximum efficiency, save electricity, and minimize risks of damage or production interruption.

Conclusion

Maintaining industrial boilers is not only a technical requirement but also part of a smart equipment management strategy for businesses. Whether you are using electric industrial boilers or large fuel-fired boilers, Maruse Engineering is always ready to accompany you in consulting, maintenance, and optimizing the operation of industrial thermal systems.

Contact Maruse today for tailored boiler solutions that best fit your production needs!