1. Introduction

Industrial boilers are indispensable equipment in modern production lines. From food processing to chemical manufacturing, boilers generate high-pressure heat and steam – key factors for efficient operation.

In this article, we will explore: what industrial boilers are, how they work, the popular types available today, and practical applications across industries in Vietnam.

2. What is an industrial boiler?

2.1 Definition

An industrial boiler (also known as a steam boiler) is a thermal industrial device used to boil water and generate high-pressure steam. This steam is used for heat transfer, machinery operation, or processes that require large amounts of heat.

2.2 Comparison with household boilers

- Industrial boiler: High capacity, used in production, with strict safety control systems.

- Household boiler: Used in homes, small scale, lower pressure and technical requirements.

2.3 Why do businesses need boilers?

- Provides fast and stable heat for production lines

- Energy saving thanks to heat recovery capability

- Meets industrial hygiene and safety standards

3. Operating principle of industrial boilers

Industrial boilers work on the principle of boiling water to produce high-pressure steam for use in production and heat transfer.

3.1 Step-by-step operation process

Industrial boilers operate in a closed cycle with four main steps:

- Water supply: Clean water is pumped into the tank or piping system through a specialized pump system.

- Heating via combustion chamber: The heat source (electricity or fuel such as oil or gas) is activated in the combustion chamber to boil the water.

- Steam generation and accumulation: When boiling point is reached, water turns into high-pressure steam and is temporarily stored in the chamber.

- Steam delivery to end equipment: Hot steam is delivered through pipelines to production zones such as dryers, presses, or secondary heat exchangers.

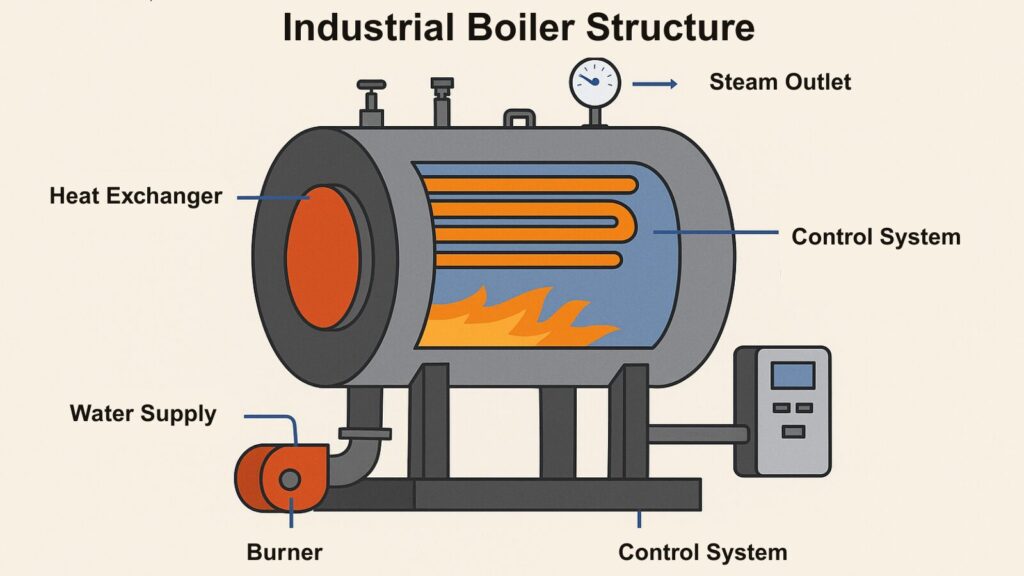

3.2 Main components

To ensure efficient and safe steam generation, an industrial boiler consists of the following components:

- Combustion chamber: Main heat generation zone using electric resistors or fuel burners.

- Heat exchanger: Enables quick heat transfer from chamber to water.

- Water tank: Stores water before and during heating.

- Automatic control system: Includes control panel, pressure and temperature sensors for safe and accurate operation.

- Safety valve & gauges: Monitor pressure, temperature, and ensure system safety.

3.3 Real-life example: In industrial water treatment

In industrial wastewater treatment systems, electric boilers are used to:

- Provide heat for evaporation or sludge concentration

- Sterilize output water with hot steam

- Assist in cleaning filters and treatment pipelines

Example: A beverage factory in Binh Duong uses a 150kW electric boiler to supply clean steam to an RO water filtration system, maintaining performance without using harmful chemicals.

4. Types of industrial boilers

Each type of industrial boiler has specific technical features and applications tailored to industry needs.

4.1 Electric industrial boilers

- Advantages:

- No harmful emissions

- Simple installation, space-saving

- Automatic control, high precision

- Disadvantages:

- High electricity cost for large-scale continuous use

- Suitable applications:

- Food, pharmaceutical, and water treatment industries requiring clean, pollution-free steam

4.2 Oil/gas-fired boilers

- Advantages:

- High steam generation efficiency

- Quick heating, suitable for instant-response production lines

- Disadvantages:

- Emits gases, requiring exhaust treatment

- Requires regular burner maintenance

- Suitable applications:

- Textile, plastic, and chemical industries needing stable high energy

4.3 Coal-fired boilers

- Advantages:

- Low fuel cost, easily sourced locally

- Disadvantages:

- Environmental pollution, ash and slag generation

- Requires large installation area

- Suitable applications:

- Large-scale industries in areas with cheap coal such as construction material or ceramic tile manufacturing.

5. Applications of industrial boilers

Industrial boilers are widely used in many fields due to their flexible steam supply capabilities.

5.1 Food and beverage industry

- Sterilizing, steaming, cooking raw materials

- Bottle/jar cleaning and pipe sanitation

- Maintaining stable fermentation temperature

5.2 Textile industry

- Steam for dyeing machines, drying, and industrial ironing

- Maintains color quality and fabric durability

5.3 Wastewater treatment and industrial water filtration

- Sterilizing clean water with steam

- Heating during sludge separation or deodorization stages

- Applied in RO, UF filtration systems

5.4 Chemical and plastic industry

- Maintains stable chemical reaction temperature

- Heats plastic materials before pressing or extrusion

- Supplies steam to distillation towers or reactors

6. Benefits of using modern industrial boilers

Using modern industrial boilers helps businesses optimize costs, improve productivity, and ensure production safety.

6.1 Energy saving and operational cost reduction

- New technologies help optimize thermal efficiency

- Reduce energy loss through insulation and steam reuse

- Suitable for businesses wanting long-term energy cost control

6.2 Enhanced automation and safety

- Automatic control systems monitor pressure, temperature, and water levels continuously

- Integrated protection functions such as automatic shut-off when overloaded

- Reduce reliance on manual labor, minimize accident risks

6.3 Environmentally friendly

- Electric industrial boilers produce no harmful emissions

- Easily meet environmental standards like ISO 14001, GMP

- Reduce air and noise pollution in factories

6.4 Production process optimization

- Stable steam supply boosts production speed and quality

- Flexible capacity expansion based on actual demand

- Easily integrates into modern industrial production lines

7. Conclusion & Consultation

Industrial boilers are essential thermal solutions that enhance efficiency and save production costs. Based on actual needs and industries, businesses can choose the most suitable boiler type.

Contact Maruse Engineering today for consultation on efficient, safe, and economical electric boiler solutions for your business.