In manufacturing industries such as food, beverages, pharmaceuticals, chemicals, textiles, laundry services, and hotels, boilers are an indispensable energy source. Industrial boiler systems play the role of the “heart” of the factory, operating continuously to supply steam for cooking, drying, steaming, sterilization, disinfection, fabric processing, equipment cleaning, and more.

However, investing in a boiler is not simply about purchasing a steam-generating device. If the capacity, fuel type, or supplier is selected incorrectly, businesses may face risks such as:

- high energy consumption,

- high maintenance costs,

- failure to meet safety standards or suspension due to technical regulation violations,

- production interruptions and loss of customer trust.

To help businesses avoid these mistakes, the article below summarizes 7 key factors that must be checked before investing in a boiler for factories.

1. Identify steam demand and appropriate boiler capacity

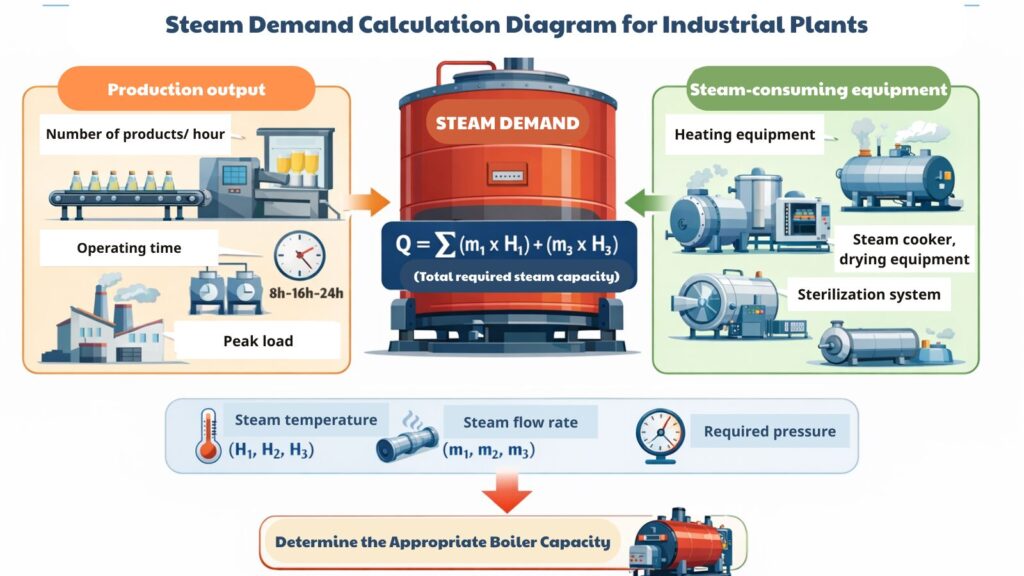

1.1 Calculate actual steam demand

This is the most important step before selecting a boiler. Businesses need to determine:

- Average steam consumption per hour

- Production output per shift, per day, or per season

- Steam demand during peak load periods

If an industrial boiler is selected with insufficient capacity, the steam supply will be inadequate and disrupt production lines. If the capacity is too large, energy costs will increase, leading to wasted investment.

1.2 Allow for future production growth

Many businesses are forced to replace their entire boiler system when expanding factories because the initial capacity was too small. Expert recommendations include:

- Choosing designs that can be upgraded or expanded

- Prioritizing boilers that allow additional modules to increase capacity

Proper planning can help save 30–50% of future investment costs.

>>> Related articles:

Should you choose a low-cost industrial boiler?

How to properly maintain industrial boilers

2. Choose the appropriate boiler type for the intended application

Each factory has different steam demands and operating environments, so businesses must select the appropriate industrial boiler to ensure efficiency and safe operation.

2.1 Fire-tube boiler

Fire-tube boilers are suitable for factories with medium-pressure steam demand and stable operation. This type of boiler is commonly used in textile factories, laundry facilities, hotels, and resorts.

Advantages: Simple operation and low initial investment cost, allowing easy deployment without complex technical systems.

2.2 Water-tube boiler

Water-tube boilers are the optimal choice for industries requiring high sterilization temperatures or large steam capacity, such as food and beverage, chemical production, and production lines operating at high pressure.

Advantages: High heat transfer efficiency, rapid pressure increase, and high safety performance under heavy load conditions.

2.3 Industrial electric boilers – a new trend for modern enterprises

Industrial electric boilers are becoming a popular choice thanks to their clean and flexible operation.

Key features include:

- No smoke or dust emissions – suitable for industries requiring high hygiene and safety

- No fuel storage required

- Easy operation, low maintenance, high automation

- Compliant with environmental standards and clean energy orientation in Vietnam

>>> Related article:

Introduction to industrial electric boilers – the green trend

3. Energy efficiency and operating costs

3.1 Boiler efficiency and its impact on long-term costs

The efficiency of an industrial boiler directly determines how much energy is consumed during operation. When a business chooses a high-efficiency boiler, the equipment uses less fuel or electricity to produce the same required amount of steam. This helps reduce production costs over time and minimizes heat loss. In contrast, if a low-efficiency boiler is used, operating costs will increase and place greater pressure on the factory’s long-term budget.

Therefore, when comparing prices, do not look only at the initial purchase cost, but also consider:

- Heat exchange efficiency

- Heat loss rate

- Waste heat recovery mechanism

- Energy-saving capability

Investing in a high-efficiency boiler can help businesses save 15–30% on electricity/fuel each year.

3.2 Industrial electric boilers – an optimal solution for energy-saving factories

Industrial electric boilers use electricity as the primary energy source, enabling fast and stable steam generation. With automatic control technology, electric boilers help:

- precisely control temperature

- maintain stable operation

- reduce labor costs

- eliminate losses from combustion

This is why electric boilers are increasingly used in the pharmaceutical, beverage, and food industries.

In addition, when operating an electric boiler, businesses do not need to allocate space for fuel storage, which further reduces costs and installation footprint. Thanks to these characteristics, electric boilers have become an optimal solution for factories pursuing energy savings and hygiene standards.

4. Safety factors and mandatory legal standards

A boiler that does not meet safety requirements can cause explosions and result in damages worth billions of VND. Therefore, businesses should check the following:

4.1 Inspection certificates and technical standards

Each industrial boiler must undergo an inspection process in accordance with Vietnamese regulations before being put into operation. Businesses must ensure that the equipment fully complies with technical standards such as:

- QCVN 01:2008/BLĐTBXH

- TCVN 7704:2007

- Regulations on the inspection of equipment subject to strict safety requirements

Following the inspection process correctly not only helps businesses operate steam systems safely, but also avoids legal risks and unexpected costs caused by operational suspension.

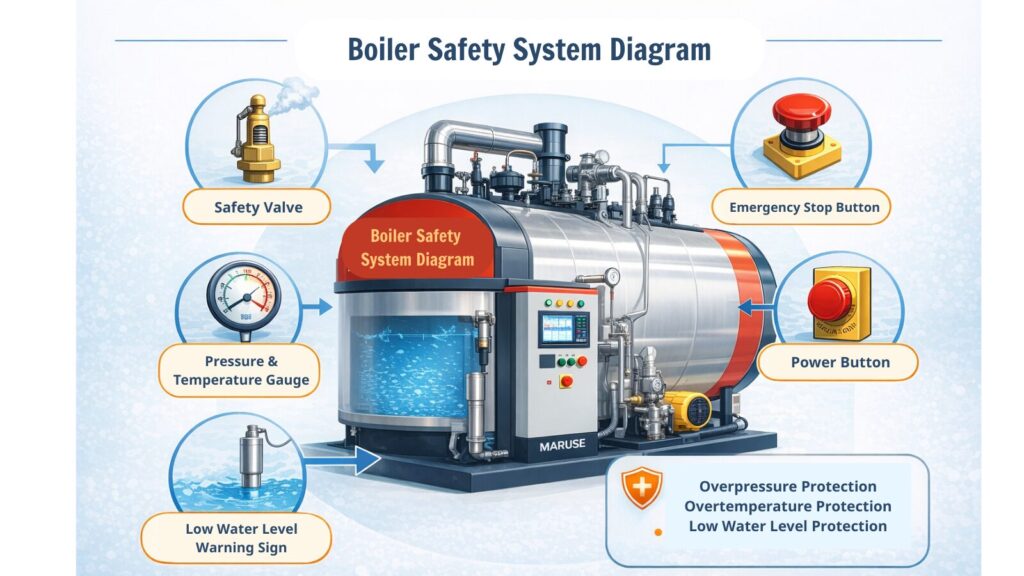

4.2 Associated safety systems

A compliant boiler must be equipped with a complete protection system for potential risks during operation. Businesses should verify the presence and proper functioning of devices such as a safety valve, pressure–temperature gauge, low-water warning sensor, and an emergency stop button. These components help prevent overpressure, overheating, or low-water incidents, ensure stable operation, and protect operators from workplace safety risks.

When these safety devices work properly and meet standards, the boiler can maintain stable performance and extend its service life.

In particular, businesses should not use boilers with unclear origin or without technical certification.

5. Fuel use and environmental impact

5.1 Choosing the right fuel

The type of fuel used in an industrial boiler directly affects operating costs, energy consumption, and the ability to meet production requirements. Businesses should identify the most suitable local energy source.

Below are common options used by businesses:

| Fuel type | Advantages | Disadvantages | Applications |

| Electricity | Clean, safe | Higher cost | Pharmaceuticals, beverages |

| Gas | High capacity, clean | Installation cost | Food factories |

| Oil | Easy installation | Higher emissions | Light industry |

5.2 Environmental impact and the trend toward clean fuels in Vietnam

When operating fuel-fired boilers, businesses must pay attention to emissions and environmental treatment requirements in accordance with regulations issued by competent authorities. Vietnam is applying stricter standards to reduce industrial emissions, so factories should:

- select compliant flue gas treatment systems

- prioritize clean fuels

- limit coal use within industrial zones

Adopting clean fuels not only enhances brand image, but also aligns with today’s sustainable development direction.

6. After-sales service and long-term maintenance capability

6.1 Why is after-sales service a key factor?

Boilers operate continuously under high pressure, so after-sales service plays a decisive role in the system’s lifespan and performance. When the supplier commits to periodic maintenance, businesses can maintain stable efficiency, minimize breakdown risks, and avoid production line interruptions. Comprehensive after-sales service also helps reduce repair costs and enables better operational planning.

If maintenance is not performed, the following issues may occur:

- reduced efficiency

- increased fuel consumption

- higher risk of explosion

Therefore, when choosing a supplier, businesses should consider these criteria:

- a professional technical team

- a standard maintenance procedure

- genuine replacement parts supply

6.2 Benefits of choosing a reputable supplier like Maruse Engineering

Maruse not only supplies boilers, but also provides:

- steam system design consultation

- inspection and periodic maintenance

- operation training

- 24/7 technical support

A reputable boiler supplier typically has an experienced technical team and a clear maintenance process. By partnering with a professional provider, businesses can access genuine spare parts, operation manuals, and timely technical support throughout the equipment’s lifecycle. This is the key difference that helps businesses operate with confidence throughout the boiler’s service life.

7. Future scalability

7.1 Modular design – a solution for capacity expansion

As factories grow, businesses may need to increase capacity or expand production lines. An industrial boiler with a suitable design allows module upgrades or accessory additions without replacing the entire system. This scalability helps businesses save on new investment costs and ensures continuity of operations.

If a business plans to increase capacity after 6–12 months, it should choose:

- a boiler that supports modular upgrades

- a structure that allows increases in pressure/heating elements/heating heads

7.2 Integrating smart management systems

Many modern boiler models support smart control features, remote parameter monitoring, and real-time fault alerts.

Modern factories apply IoT to monitor:

- steam levels

- operational efficiency

- energy consumption

- real-time fault alerts

Applying smart management solutions helps improve equipment utilization efficiency, optimize the entire production line, and support businesses in making accurate investment decisions in the future.

Conclusion

Investing in an industrial boiler is a decision that significantly impacts operating costs, efficiency, and factory safety. Missing just one of the seven factors above may cost businesses money, time, and reputation.

👉 If you are looking for a boiler solution for your factory, let Maruse Engineering accompany you.

Contact us today to receive consultation on a steam system tailored to your production needs.

Website: https://www.marusevn-boiler.com