During the process of industrialization and modernization, the demand for industrial boilers has significantly increased across various sectors such as food processing, pharmaceuticals, laundry services, textiles, chemicals, and hospitality. While businesses previously relied on oil-fired, coal-fired, or biomass boilers, industrial electric boilers are now emerging as a new option that aligns with the “green manufacturing” trend—cleaner, safer, and more efficient.

The shift toward low-emission operating models has become increasingly evident, especially in Vietnam, where companies must comply with environmental standards, emission control regulations, and global supply chain requirements. In this context, industrial electric boilers have emerged as an effective replacement for traditional boiler systems.

1. Industrial boilers and the distinction of electric boilers

1.1. Definition of industrial boilers

Industrial boilers are a type of industrial thermal equipment that use energy to generate steam or hot water under high pressure, serving various production processes such as heating, steaming, drying, sterilizing, cleaning, or powering machinery.

They are a critical system in modern production lines, acting as the “thermal heart” that keeps operations running continuously and efficiently.

1.2. Differences between electric boilers and traditional boilers

There are two common types:

| Boiler type | Fuel source | Characteristics |

| Gas/oil/coal-fired boiler | Fossil fuel | Generates exhaust gases and requires an emission treatment system; complex operating procedures |

| Industrial electric boiler | Electricity | No on-site emissions, simplified operation, higher safety |

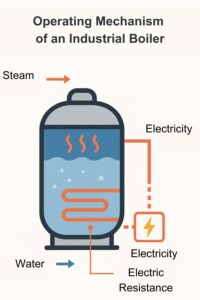

The advantage of industrial electric boilers lies in their ability to convert nearly all electrical energy into heat without producing smoke or dust, making them suitable for sustainable development criteria set by leading corporations worldwide.

2. Outstanding advantages of industrial electric boilers in the green production trend

2.1. High efficiency – optimizing production costs

Unlike coal-fired or biomass boilers, industrial electric boilers do not require combustion chambers and do not lose energy through exhaust gases. This improves energy conversion efficiency and allows businesses to:

- Reduce fuel consumption

- Easily adjust operating capacity based on production needs

- Save maintenance costs for the system

2.2. Zero direct emissions – an environmentally friendly solution

In the ESG and Net-Zero era, businesses are not only concerned about cost but also about environmental responsibility, including:

- Reducing CO₂, SO₂, and NOx—major greenhouse gases

- Eliminating the generation of PM2.5 fine dust

- Avoiding the need for complex exhaust treatment systems

Industrial electric boilers are suitable for industries that require sterile and contamination-free production environments.

2.3. Safe, simple operation with reduced risks

With a streamlined structure and automated control system, electric industrial boilers provide:

- No explosion risk from fossil fuels

- Reduced operator manpower

- Precise temperature and pressure control

- Fast start-up without manual ignition

2.4. Supporting sustainable development goals

As Vietnam commits to achieving Net Zero emissions by 2050, factories adopting industrial thermal equipment powered by electricity will:

- Gain competitive advantages when joining FDI supply chains

- Easily meet export standards in strict markets such as the EU and Japan

This is why industrial electric boilers have become a strategic choice for many businesses in the era of green production.

3. Practical applications of industrial electric boilers in manufacturing industries

3.1. Food and beverage industry

- Clean steam used for sterilization, cooking, and pipeline sanitation

- Compliant with HACCP/GMP

>>> Related article: Applications of boilers in the food industry: Standards & operational efficiency

3.2. Textile & fashion industry

- Steam used for dyeing, fabric shaping, drying, and color processing

- Odor-free, smoke-free—ensuring fabric quality and a clean environment

3.3. Chemical industry

- Stable steam and precise temperature control for chemical reactions

- Industrial electric boilers ensure continuous operation without explosion risks

3.4. Pharmaceutical & cosmetics industry

- Clean steam used during preparation and equipment sterilization

- Compliant with GMP-WHO

>> Related article: Industrial electric boilers in the pharmaceutical industry: Standards & applications

3.5. Industrial laundry & hospitality services

- Steam supplied for ironing machines, steamers, and hot-water systems

- No need for exhaust vents—ideal for confined spaces

3.6. Other sectors

- Wood processing factories

- HVAC systems

- Spas and sauna centers

4. The green transition of the boiler industry – The future of sustainable production

4.1. Global transition

Over the past decade, countries and multinational corporations have accelerated sustainable development strategies toward carbon neutrality. This makes it no longer optional but mandatory for businesses to reduce carbon emissions according to global environmental standards such as COP26, ISO 50001, and ESG requirements imposed by global supply chains.

Beyond improving operational efficiency, businesses must demonstrate compliance through ESG reports (Environmental – Social – Governance). This has become a prerequisite for joining supply chains and forming long-term partnerships with international customers. In this context, industrial electric boilers are considered a suitable solution to help companies reduce emissions directly at their facilities and establish a forward-thinking green image.

4.2. Increasingly strict environmental regulations

Industrial zones, export processing zones, and major manufacturing corporations in Vietnam are tightening environmental assessment criteria, especially for sectors with high energy consumption. New requirements include:

- Boiler systems with zero direct emissions, free from smoke and air pollutants

- Monitoring and reporting of energy consumption in accordance with ISO 14064 for transparent management of greenhouse gas emissions

Companies that continue to use oil-fired or coal-fired boilers must invest heavily in emission treatment systems, maintenance, and periodic inspections. In contrast, industrial electric boilers eliminate these challenges by operating on electricity and producing no onsite emissions. This provides significant advantages during environmental assessment and facility expansion.

4.3. Electric boilers – A competitive advantage for the future

In the race toward clean energy transformation, industrial electric boilers not only help businesses reduce emissions but also enhance cost efficiency and brand reputation. With resistance-based heating mechanisms, these systems offer:

- Lower long-term operating costs due to the absence of fossil fuel consumption and reduced energy loss

- Minimal maintenance requirements thanks to the lack of combustion residue, combustion chambers, and moving parts

- Enhanced safety with reduced explosion risks and simplified inspection procedures

With these advantages, businesses using industrial electric boiler systems can easily meet the expectations of international buyers—particularly in industries requiring clean energy and traceable production sources. This becomes a competitive advantage that elevates brand value, facilitates export expansion, and accelerates global supply chain integration.

Conclusion

Industrial electric boilers are no longer just thermal equipment but have become a strategic solution in the green transition journey of businesses. With their clean, stable, and safe operation suitable for various industries, they represent a forward-looking choice for enterprises aiming for sustainable growth.

👉 Contact Maruse Engineering for consultation on industrial boiler systems tailored to your industry, budget, and business expansion plan.